Enhancing Workplace Safety: The Important Role of Anti-static PVC Sheets in the Electronics Industry

Release time: 2025-02-10

In the modern electronics industry, static electricity is a significant issue. Static electricity can damage precision equipment, cause production downtime, and even result in financial losses. To effectively prevent static electricity from harming equipment and personnel, anti-static PVC sheets have become an essential protective material, increasingly used across the electronics industry. This article explores the role of anti-static PVC sheets in the electronics industry and how they help enhance workplace safety.

What are Anti-static PVC Sheets?

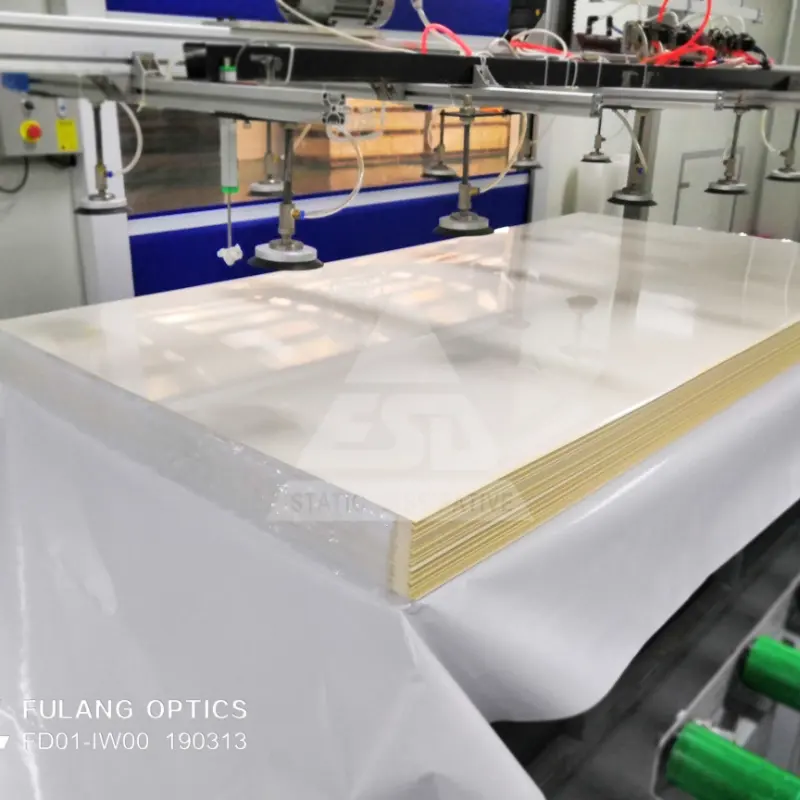

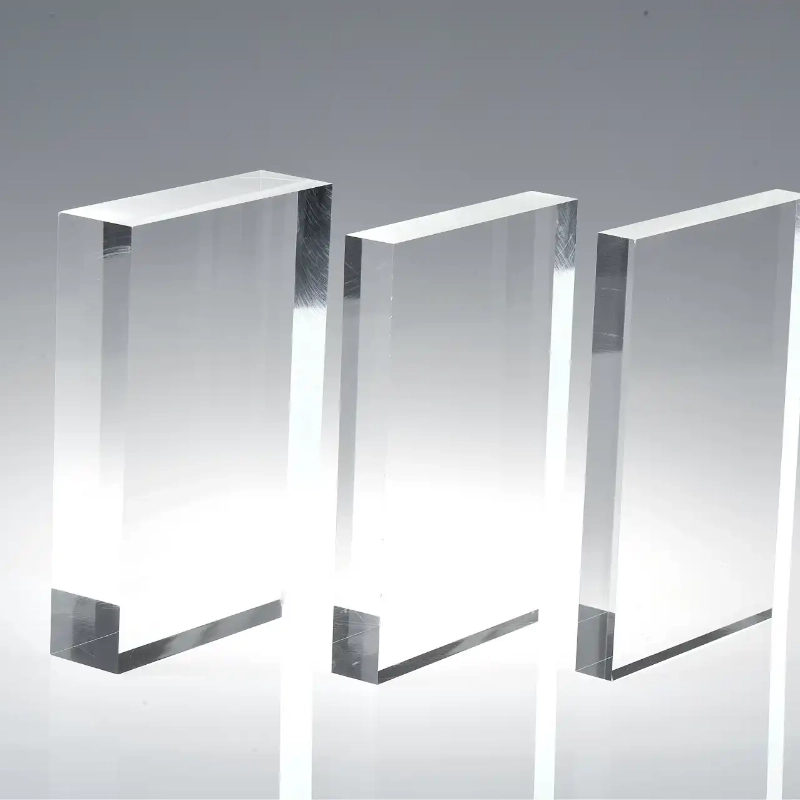

Anti-static PVC sheets are plastic sheets with anti-static properties. They achieve this by incorporating anti-static agents during the manufacturing process or by employing special surface treatment techniques that prevent static accumulation. Unlike regular PVC sheets, anti-static PVC sheets can effectively dissipate static electricity and prevent electrostatic discharge (ESD) from damaging electronic components and equipment.

Applications of Anti-static PVC Sheets in the Electronics Industry

Electrostatic discharge is one of the primary causes of equipment failure and production interruption in the electronics industry. Electronic components and circuit boards are extremely sensitive during production, assembly, and transportation, and ESD can cause short circuits, component damage, or even complete failure. Therefore, ensuring a production environment free from static interference is critical.

The application of ESD PVC sheets in the electronics industry is most evident in the following areas:

- Protecting Electronic Components from Static DamageDuring the production of electronic products, static accumulation can be transferred to sensitive components through human contact or equipment, potentially causing damage. Anti-static PVC sheets effectively suppress static build-up, thereby protecting electronic components from electrostatic damage.

- Improving Workplace SafetyStatic electricity accumulation in production workshops not only poses a risk to equipment but also to employees. By using anti-static PVC sheets on the workshop floor, walls, and workstations, the generation of static can be significantly reduced, improving workplace safety and lowering the risk of static-related incidents for employees.

- Enhancing Product Quality and Production EfficiencyStatic electricity can affect the quality of electronic components and may also cause unnecessary downtime in production. By using anti-static PVC sheets, the risk of equipment failure due to static discharge is minimized, thus improving production line stability and efficiency.

Advantages of Anti-static PVC Sheets

- Effective Anti-static PerformanceThe main advantage of anti-static PVC sheets is their excellent anti-static properties. With careful design and the addition of anti-static materials, these sheets quickly dissipate accumulated static, effectively preventing electrostatic discharge.

- Durability and Easy MaintenanceAnti-static PVC sheets are highly durable, resistant to wear and corrosion, making them suitable for long-term use. Additionally, their smooth surface is easy to clean and maintain, helping to keep the production environment neat and organized.

- Cost-effectivenessCompared to other anti-static materials, anti-static PVC sheets are relatively economical and suitable for large-scale applications. They effectively enhance workplace safety and prevent costly repairs due to static damage, making them a highly cost-effective choice.

- Adaptable to Various Work EnvironmentsAnti-static PVC sheets are not only used in the electronics industry but also in semiconductor manufacturing, laboratories, medical device production, and other industries requiring static protection. Their versatility and wide applicability make them the material of choice in many industrial sectors.

Flomctech: Professional Anti-static PVC Sheet Manufacturer

As a leading anti-static PVC sheets manufacturer, Flomctech focuses on providing high-quality anti-static sheet solutions. Flomctech anti-static PVC sheets offer significant advantages in the electronics industry, effectively protecting sensitive electronic equipment from static damage. Whether used in production environments, equipment protection, or in sensitive areas such as laboratories, Flomctech’s anti-static materials provide stable and efficient protection. With years of industry experience, Flomctech is dedicated to providing customized anti-static products to meet the needs of various industries.

As electronic technology continues to develop, the demand for static protection is growing. Thanks to their excellent anti-static performance, durability, and cost-effectiveness, anti-static PVC sheets play a crucial role in the electronics industry. By using anti-static PVC sheets, companies can significantly reduce static damage to equipment and products, ensure stable production lines, and enhance overall workplace safety and production efficiency. In the future of electronic manufacturing, anti-static PVC sheets will continue to safeguard workplace safety, and Flomctech will be your reliable partner, providing top-quality anti-static solutions.