FLOMC ESD Orange anti-static PC sheets play an important role in various high-tech fields such as electronics, communication, medical, automotive electronics, and industrial automation. Its excellent anti-static performance and physical properties make it an ideal choice for these industries, providing reliable electrostatic protection solutions for electronic devices, communication equipment, medical devices, automotive electronics, and industrial automation.

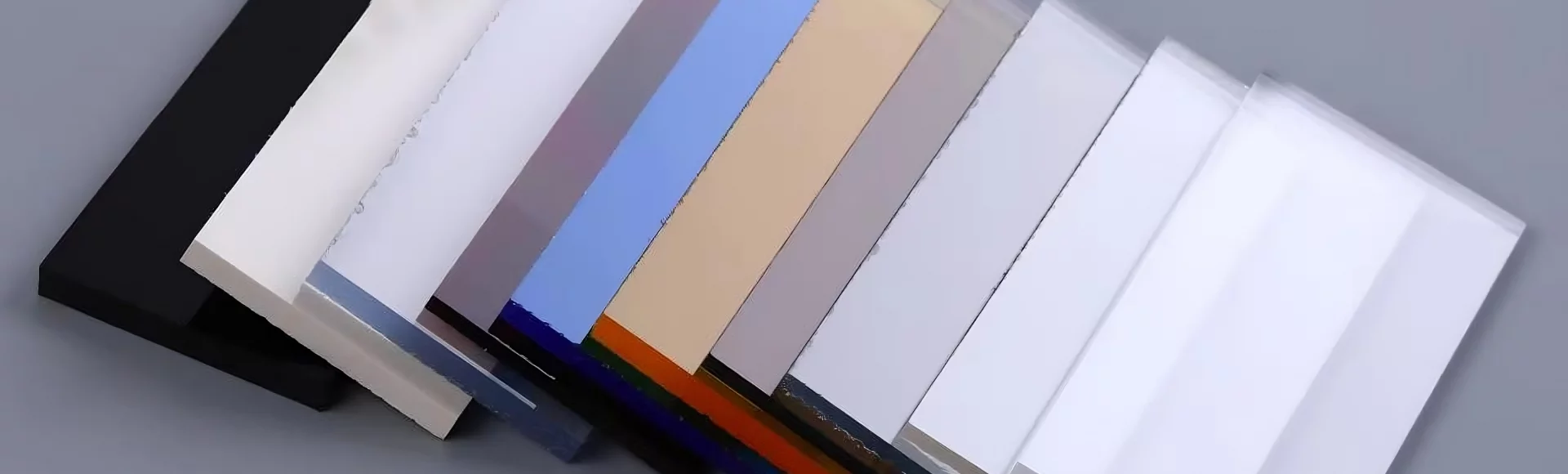

Products

Detailed parameters

Product specifications

- Available thickness range: 1mm-20mm

- Sheet dimensions: 1000x2000mm,1200x2400mm,1220x2440mm or customize

- Weight: Density 1.2kg/sqm, half weight of glass.

Quality Standards

- Compliance with international quality and safety standards (e.g., ISO, ASTM, UL, AS, CE)

- In-house quality control measures

- Third-party inspection and certification (if applicable)

- Warranty or guarantee offered on the products

Variety Specifications

| Class | Functional model | Color | Size/Thickness(mm) | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 8.0 | 10.0 | -20.0 | |

| Orange Anti-static PC Sheet | PFD03 | CR00 | Transparent | 1000*2000 | ② | ② | ① | ① | ||||

| 1200*2400 | ② | ① | ① | ① | ② | ② | ③ | ③ | ||||

| PFD03 | TY00 | Tea color | 1000*2000 | ② | ② | ② | ||||||

| 1200*2400 | ② | ② | ② | |||||||||

| PFD03 | BK00 | Black | 1000*2000 | ② | ||||||||

| 1200*2400 | ② | ② | ||||||||||

①Items in stock ②Cycle products ③Customized products

#For other colors and specifications, please contact us.

Yellow Anti-static PC Sheet properties table

| Product Name | Orange Anti-static PC Sheet | ||

| model | PFD03-CR00 | ||

| Thickness(mm) | 5 | ||

| Specification(mm) | 1000×2000 1200×2400 1220×2400 | ||

| Basic performance | proportion | ASTM D792 | 1.2 |

| Light transmittance(%) | ASTM D1003 | 85 | |

| Haze(%) | ASTM D1003 | 0.9 | |

| Tensile strength at break(MPa) | ASTM D638 | 71 | |

| Stretch rate(%) | ASTM D638 | 115 | |

| Elasticity(MPa) | ASTM D790 | 88 | |

| Impact resistance(KJ/m²) | ASTM D256 | 13 | |

| Rockwell hardness | ASTM D785 | 76 | |

| Thermal deformation | ASTM D648 | 127 | |

| Coefficient of thermal expansion (/℃) | ASTM D696 | 5.2×10^-5 | |

| Water absorption rate | ASTM D570 | 0.15 | |

| Pencil hardness | ASTM D3363 | HB | |

| Steel wire test | 0000#,500g,500times | Slightly Scratched | |

| Combustibility | ASTM D635 | Self-exting uishing | |

| Flame retardant grade | UL-94 | V-2 | |

Remarks:Take 5mm as an example. It can be customized according to customer needs. Due to different base materials and different environments, the results may have ± deviations (the final testing standard is subject to our company. The above data is representative data, not guaranteed values. Please use it as a reference value.

Chemical resistance test (surface drip test: 24h at 23℃ 50%RH)

| Chemical Name | concentration | Antistatic properties | Appearance Changes | |

| PC | PC | |||

| Acid and Base | hydrochloric acid | 36% | ⭕ | ⭕ |

| 20% | ⭕ | ⭕ | ||

| Hydrogen Peroxide | 10% | ⭕ | ⭕ | |

| Sodium hydroxide | 40% | ⭕ | ⭕ | |

| 5% | ⭕ | ⭕ | ||

| Organic solvents | Ethanol | 100% | ⭕ | ⭕ |

| Isopropyl alcohol | 100% | ⭕ | ⭕ | |

| acetone | 100% | N.A. | X Dissolve | |

| Ethyl acetate | 100% | ⭕ | ⭕ | |

| dimethylformamide | 100% | N.A. | X Dissolve | |

| Tetrahydrofuran | 100% | N.A. | X Dissolve | |

| other | Salt water | 30% | ⭕ | ⭕ |

| Neutral detergent | 10% | ⭕ | ⭕ |

This result is the result of dripping a single solvent under stress-free conditions (short term). For long-term complex chemical environments, actual results should be used.

If the use environment is different from the above test environment, you should test it in advance and judge according to the results.

FAQ

Most frequent questions and answers

Does Orange crack easily? Can I drill pc?

pc sheet material is known for its high impact resistance and durability. To drill holes in pc, use an ordinary iron or HSS drill bit. Position the drill perpendicular to the sheet and run it at medium speed, applying light pressure. A slightly used but sharp drill bit is best to avoid “biting” into the material.

And don’t drill too close to the edge.

What is the life span of FLOMC Orange Anti-static PC sheet?

he lifespan of FLOMC Orange Anti-static PC sheet typically ranges from 10 to 15 years, depending on factors such as material quality, UV protection, environmental exposure, and maintenance. PC Sheets with UV-resistant coatings generally last longer.

How do you process pc tinted sheet?

Our Orange Anti-static PC sheets can be machined using all known machining methods.

- Drilling holes

- Even vacuum thermoforming

- Jigsaw or circular saw

- Milling angles

Recommended products

If you are interested in our products, please fill in the form below to submit information.