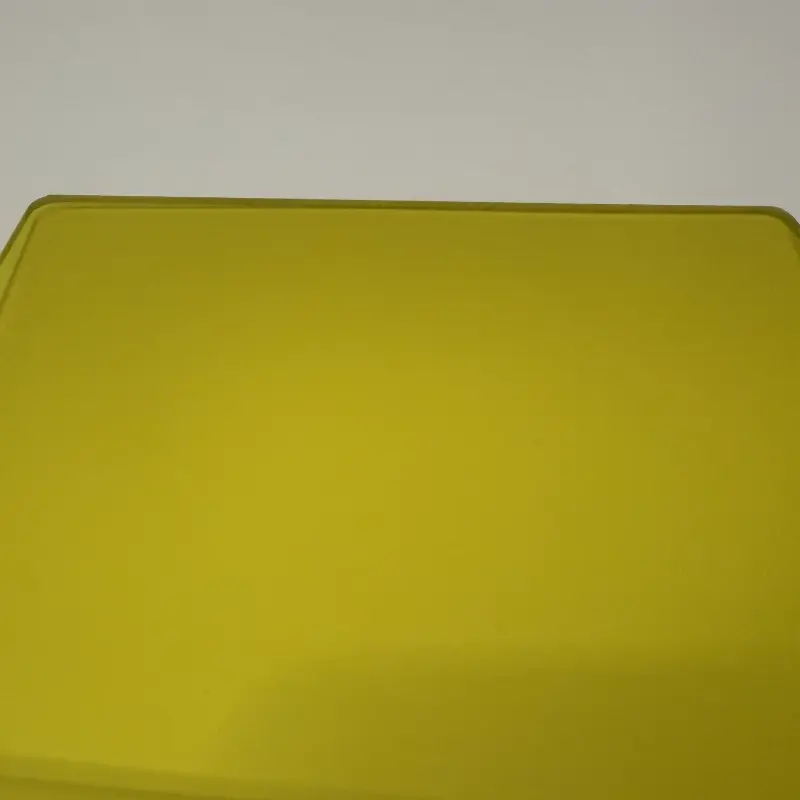

FLOMC ESD Yellow Anti-static PMMA Sheet:Antistatic organic glass sheet is a material that adds antistatic properties to PMMA (acrylic sheet) through coating technology. It retains the transparency and original physical properties of the organic sheet, and at the same time has excellent antistatic function, which is suitable for the special requirements of the high-tech era.

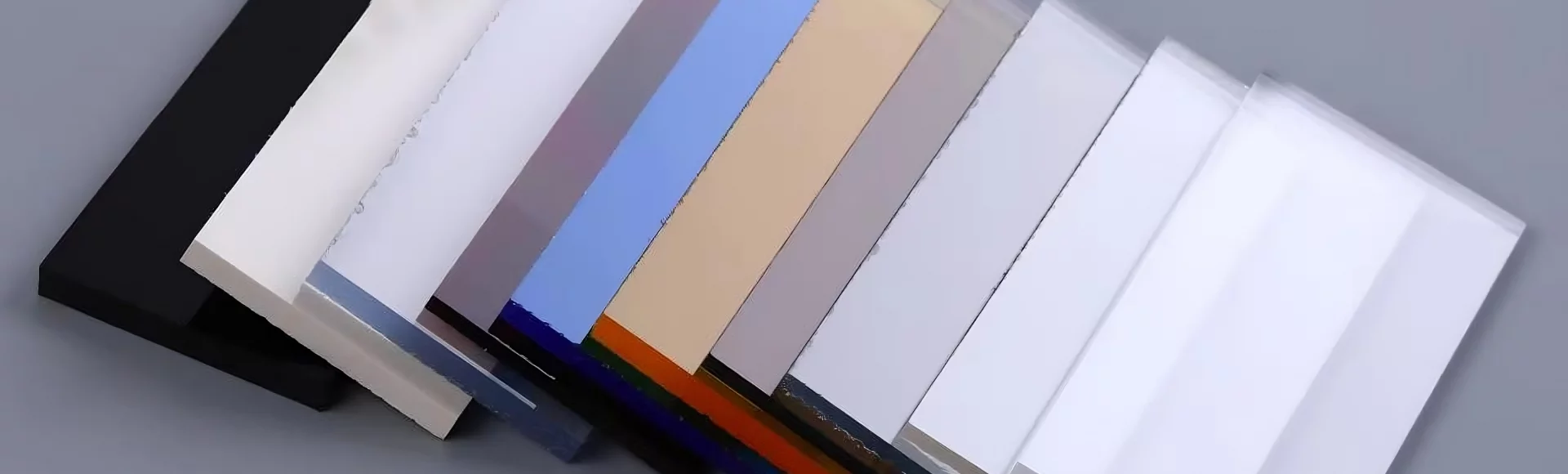

Products

Detailed parameters

Yellow anti-static acrylic sheet has excellent anti-static performance, high transmittance, chemical resistance, and mechanical properties. It is widely used in various fields such as electronics, advertising, construction, furniture, transportation, and medical care, and is suitable for various occasions that require anti-static treatment.

Product specifications

- Available thickness range: 1mm-20mm

- Sheet dimensions: 1000x2000mm,1200x2400mm,1220x2440mm or customize

- Density:1.15-1.19 g/cm³

Quality Standards

- Compliance with international quality and safety standards (e.g., ISO, ASTM, UL, AS, CE)

- In-house quality control measures

- Third-party inspection and certification (if applicable)

- Warranty or guarantee offered on the products

Variety Specifications

| Class | Functional model | Color | Size/Thickness(mm) | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 8.0 | 10.0 | -20.0 | -50.0 | |

| Yellow Anti-static PMMA | PFD02 | CR00 | Transparent | 1000*2000 | ② | ① | ① | ① | ② | ② | |||

| 1200*2400 | ② | ① | ① | ① | ② | ② | ② | ③ | ③ | ||||

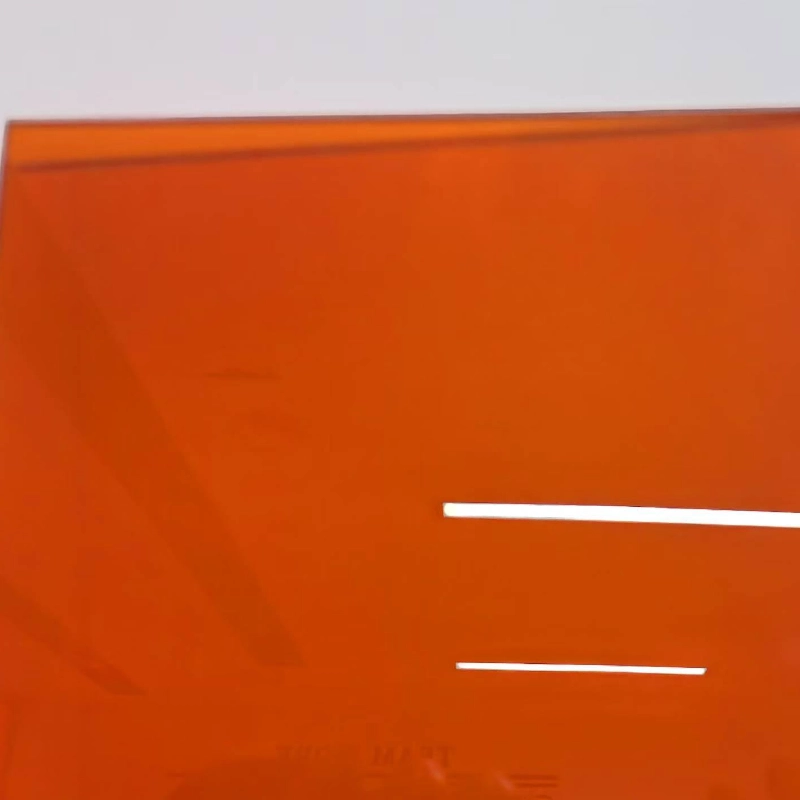

| PFD02 | 0301 | Blue | 1000*2000 | ② | |||||||||

| 1200*2400 | ② | ||||||||||||

| PFD02 | 0522 | Tea color | 1000*2000 | ② | |||||||||

| 1200*2400 | ② | ② | ② | ||||||||||

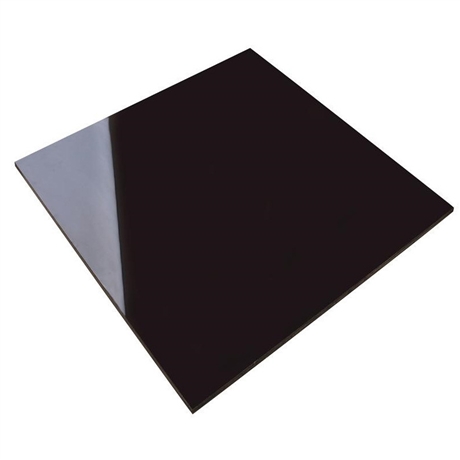

| PFD02 | 0502 | Black | 1000*2000 | ||||||||||

| 1200*2400 | ② | ||||||||||||

①Items in stock ②Cycle products ③Customized products

#For other colors and specifications, please contact us.

Yellow Anti-static PMMA sheet properties table

| Product Name | Yellow Anti-static PMMA sheet | ||

| model | PFD02-CR00 | ||

| Thickness(mm) | 5 | ||

| Specification(mm) | 1200×2400 1000×2000 | ||

| Basic performance | proportion | ASTM D792 | 1.2 |

| Light transmittance(%) | ASTM D1003 | 90 | |

| Haze(%) | ASTM D1003 | 0.4 | |

| Tensile strength at break(MPa) | ASTM D638 | 70 | |

| Stretch rate(%) | ASTM D638 | 2.5 | |

| Elasticity(MPa) | ASTM D790 | 90 | |

| Impact resistance(KJ/m²) | ASTM D256 | 1.6 | |

| Rockwell hardness | ASTM D785 | 100 | |

| Thermal deformation | ASTM D648 | 95 | |

| Coefficient of thermal expansion (/℃) | ASTM D696 | 6.0×10^-5 | |

| Water absorption rate | ASTM D570 | 0.3 | |

| Pencil hardness | ASTM D3363 | 4H | |

| Steel wire test | 0000#,500g,500times | No Scratched | |

| Combustibility | ASTM D635 | Flammable | |

| Flame retardant grade | UL-94 | HB | |

Remarks:Take 5mm as an example. It can be customized according to customer needs. Due to different base materials and different environments, the results may have ± deviations (the final testing standard is subject to our company. The above data is representative data, not guaranteed values. Please use it as a reference value.

Chemical resistance test (surface drip test: 24h at 23℃ 50%RH)

| Chemical Name | concentration | Antistatic properties | Appearance Changes | |

| PMMA | PMMA | |||

| Acid and Base | hydrochloric acid | 36% | ⭕ | ⭕ |

| 20% | ⭕ | ⭕ | ||

| Hydrogen Peroxide | 10% | ⭕ | ⭕ | |

| Sodium hydroxide | 40% | ⭕ | ⭕ | |

| 5% | ⭕ | ⭕ | ||

| Organic solvents | Ethanol | 100% | ⭕ | ⭕ |

| Isopropyl alcohol | 100% | ⭕ | ⭕ | |

| acetone | 100% | N.A. | X Dissolve | |

| Ethyl acetate | 100% | ⭕ | ⭕ | |

| dimethylformamide | 100% | ⭕ | ▲ | |

| Tetrahydrofuran | 100% | ⭕ | ▲ | |

| other | Salt water | 30% | ⭕ | ⭕ |

| Neutral detergent | 10% | ⭕ | ⭕ |

This result is the result of dripping a single solvent under stress-free conditions (short term). For long-term complex chemical environments, actual results should be used.

If the use environment is different from the above test environment, you should test it in advance and judge according to the results.

Advantage

Integrated production: The company has two major production bases in Jiangsu and Anhui, with a total of two imported extrusion production lines for substrates and two precision coating production lines. It can achieve integrated production from independent supply of substrates to functional coating.

Supply chain advantage: The company can ensure stable supply of products, meet customers’ large-scale order demands, while ensuring product quality and delivery time.

Recommended products

If you are interested in our products, please fill in the form below to submit information.